While WHMIS is essential to workplace safety, it is also complex and challenging to navigate. This article will explore five common WHMIS mistakes and how to avoid them.

-

Failure to Conduct a Workplace Hazard Assessment

One of the most common WHMIS mistakes is failing to conduct a workplace hazard assessment. This assessment is a critical first step in implementing a WHMIS program in your workplace. A workplace hazard assessment involves identifying all the hazardous materials in your workplace and assessing the associated risks.

Conducting a thorough workplace hazard assessment before implementing your WHMIS program is essential to avoid this mistake. The review should involve reviewing all materials used in the workplace, including chemicals, products, and equipment. You should also consider any potential hazards of using or handling these materials. Once you have identified all of the dangers in your workplace, you can develop a plan to control or eliminate these hazards.

-

Failure to Properly Label Hazardous Materials

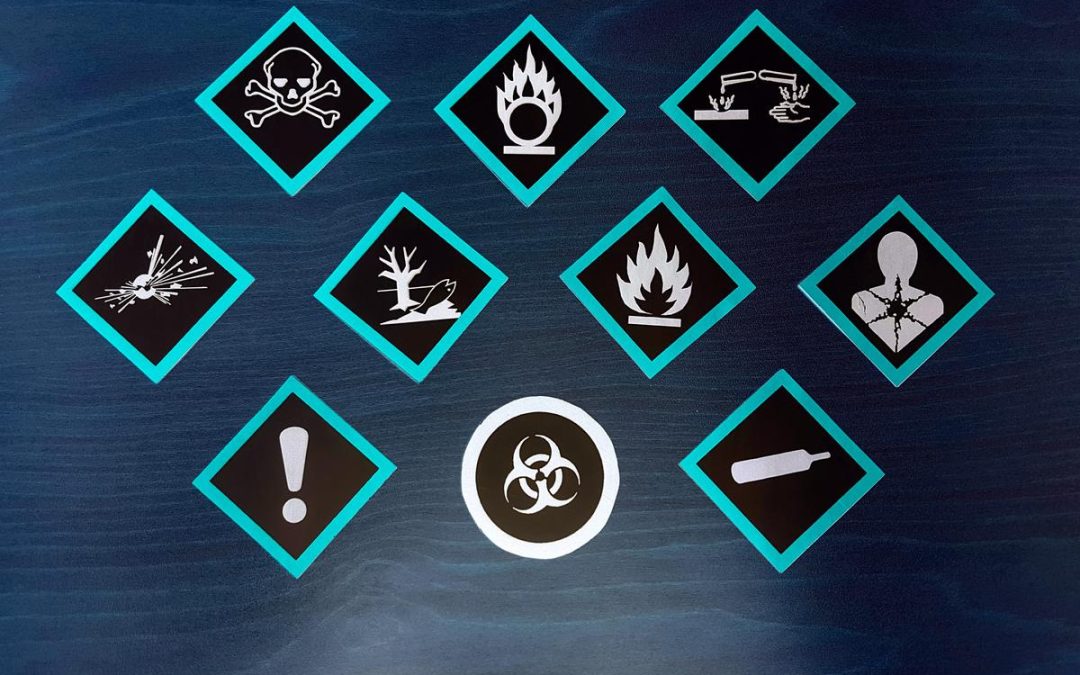

Another common WHMIS mistake is the failure to label hazardous materials properly. WHMIS requires that all hazardous materials be marked with specific information, including the product name, supplier identification, hazard symbols, and precautionary statements. Labels must be visible and legible and applied to containers of hazardous materials at the time of filling.

Training employees on the importance of adequately labelling hazardous materials is necessary to avoid this mistake. Ensure that employees understand the meaning of each hazard symbol and the information that must be included on the label. You should also have a system to ensure that all containers of hazardous materials are labelled properly before they are used.

-

Failure to Provide Adequate Safety Data Sheets (SDS)

A Safety Data Sheet (SDS) is a document that provides detailed information about hazardous material, including the hazards associated with the material, proper handling procedures, and emergency response measures. WHMIS requires that SDSs be provided for all hazardous materials used in the workplace.

The most common WHMIS mistake is the need for adequate SDSs. SDSs must be readily accessible to all employees who handle hazardous materials. They must also be updated regularly to reflect any changes in the information provided.

To avoid this mistake, it is essential to ensure that SDSs are readily accessible to all employees who handle hazardous materials. You should also ensure that SDSs are updated regularly and that employees are trained to read and understand them.

-

Failure to Provide Adequate Training

One of the most critical components of a successful WHMIS program is adequate training. All employees who handle hazardous materials must receive training on the hazards associated with these materials, proper handling procedures, and emergency response measures. One of the most common WHMIS mistakes is failing to train employees adequately. This can lead to serious safety risks and can result in workplace accidents.

To avoid this mistake, it is essential to provide adequate training to all employees who handle hazardous materials. Training should be provided on an ongoing basis to ensure that employees are updated on the latest information and procedures. You should also regularly provide refresher training to employees to ensure they retain the information provided.

-

Failure to Review and Update the WHMIS Program

Finally, the most common WHMIS mistake is needing to review and update the program regularly. A WHMIS program should be reviewed and updated annually to ensure that it continues to meet the needs of your workplace and to reflect any changes in the hazards associated with the materials used in your workplace.

To avoid this mistake, it is essential to establish a system for reviewing and updating your WHMIS program annually. This should include reviewing and updating your workplace hazard assessment as necessary, reviewing and updating SDSs for all hazardous materials used in your workplace, and annually providing refresher training to employees. It is also essential to keep up to date with any changes to WHMIS regulations and to update your program accordingly.

Conclusion

WHMIS is a critical component of workplace safety in Canada. While it can be complex and challenging to navigate, avoiding common WHMIS mistakes is essential to ensure the safety of your employees and the success of your WHMIS program.

By conducting a workplace hazard assessment, properly labelling hazardous materials, providing adequate SDSs and WHMIS safety training, and annually reviewing and updating your WHMIS program, you can create a safe and healthy workplace for your employees.